+7(495) 660 94 49 (многоканальный номер)

8 (800) 250 94 49 (бесплатный для регионов)

- Certification Of Specialists

- Laboratory Accreditation

- NDT Devices & Means

- Calibration Of NDT Funds

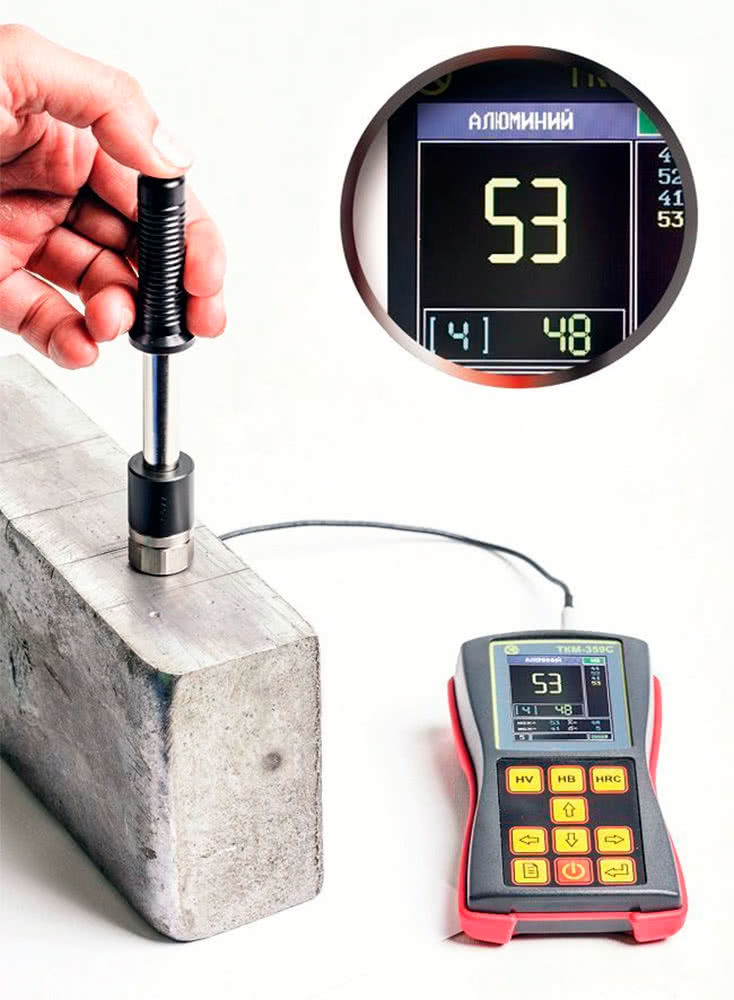

TKM-359C - dynamic hardness tester

| Retail | checkout at the office; |

| Online Starter* | entry level benefits; |

| Online 1..5* | five steps: more orders - more benefits; |

| Online Wholesale* | maximum benefit; |

| Online VIP* | individual discount. |

* valid only for orders placed on the site, according to the standard templates of contracts and accounts, it is mandatory to accept the Confidentiality Conditions for the information of an individual offer

Dynamic hardness tester TKM-359C is a high-precision device for measuring the hardness of products made of metals and alloys, including quality control of heat treatment, HFC hardening, assessment of mechanical strength in laboratory, production or field conditions. The hardness tester is used for non-destructive quality control of products in metallurgy, mechanical engineering, aircraft construction, shipbuilding, energy, nuclear and oil and gas industries.

The TKM-359C hardness tester works according to the Leeb method, in which the ratio of the rebound rate to the fall rate of an indenter with a carbide tip depends on the hardness of the material under test.

Measurements are made in basic units of hardness - HB, HRC, HV. It is also possible to control the scales HRA, HRB, HSD and ultimate strength (MPa, recalculation according to GOST 22791-77). The user can program his own scales.

Main areas of application:

- control of the strength of products during operation (gas pipelines, rails, details of structures and mechanisms);

- control of large-sized objects, which cannot be carried out on stationary hardness testers.

TKM-359C performs hardness control:

- all basic types of metals and alloys without the introduction of additional calibrations:

- structural and tool corrosion-resistant, heat-resistant, stainless steels and alloys,

- alloys of non-ferrous metals, cast irons, aluminum, bronze, brass;

- surface-hardened and hardened products (hardening with high frequency current, etc.);

- products of complex configuration (gear teeth, pipes, shafts);

- heavy and large objects with a rough surface (gas pipelines, rails, structural details).

The specialized system of statistical processing of measurement results implemented in the hardness tester allows calculating during the measurement and during the subsequent processing of the stored results in the device's memory.

Processing during measurements includes:

- maximum, minimum, mean, standard deviation from the mean;

- average deviation from the value set by the user, the number of results is more / less than the value, the maximum deviation up / down from the value;

- the number of results that go beyond the upper / lower limit of the range (set by the user), the maximum deviation from the upper / lower limit;

- automatic rejection of results, incorrect measurements;

- demonstration of all measurement results in a series.

Processing the results in the memory of the device allows you to:

- calculation of the average value, standard deviation;

- calculation of the maximum and minimum in the group of measurement results;

- calculations relative to the set values of hardness;

- sampling of results relative to the specified values of hardness;

- construction of graphs on the display of the hardness tester: relative to the average value; value or range specified by the user.

Requirements for the controlled item:

- products weighing more than 5 kilograms and more than 6 mm thick - do not require additional measures;

- products of a rigid structure (for example, pipes) with an expected hardness of 90 to 250 HB, and a thickness of more than 4 mm - do not require additional measures;

- other products - must be fixed ("rubbed in") on the base plate using fixing paste (for example, CIATIM grease).

The roughness of the tested surface providing the highest measurement accuracy (not requiring an increase in the number of averaging):

- for "D" type sensor - 3.2 Ra;

- for "G" type sensor - 7.6 Ra;

- for sensor type "E" - 3.2 Ra.

- A wide range of controlled metals with various physical and mechanical properties.

- Possibility of identifying materials in procurement production.

- Low sensitivity to product curvature and surface roughness.

- Control of the nature of changes in hardness on the surface of the product

- Control of "bulk hardness".

- Measurement of hardness in hard-to-reach places.

- The spatial position of the sensor does not affect the measurement result.

- An alarm is provided about the measurement result exceeding the set limits.

- Equipped with additional interchangeable probes with different dimensions, spring rate, indenter hardness and positioning nozzle.

- Shockproof, rubberized, dust and moisture resistant housing.

- The intuitive interface complies with the world standards of computing technology and is organized according to the "PLUG AND WORK" principle.

- The bright color graphic display functions even at subzero temperatures, allowing you to clearly see the readings in any light.

- Unique statistical processing system.

- Flexible memory organization for recording measurement results and subsequent analysis.

- Prompt correction of instrument readings by one or 2 exemplary test blocks.

- Programming:

- additional calibrations to the hardness tester scales using no more than 2 control samples;

- additional scales using from 2 to 10 control samples.

- электронный блок твердомера ТКМ-359С со встроенным аккумулятором;

- датчик тип "D";

- зарядное устройство;

- руководство по эксплуатации (совмещенное с паспортом);

- свидетельство о поверке (или отметка в РЭ);

- программное обеспечение на CD-диске;

- USB-кабель для подключения к ПК;

- чехол и манжета для закрепления прибора на груди (руке);

- сумка для переноски и хранения.

- электронный блок твердомера ТКМ-359С со встроенным аккумулятором;

- датчик тип "D" с разъемом;

- соединительный кабель к твердомерам серии ТКМ-359 - 2 шт.;

- насадка "Z-359";

- контрольный образец твердости НВ;

- зарядное устройство;

- руководство по эксплуатации (совмещенное с паспортом);

- свидетельство о поверке (или отметка в РЭ);

- программное обеспечение на CD-диске;

- USB-кабель для подключения к ПК;

- чехол и манжета для закрепления прибора на груди (руке);

- сумка для переноски и хранения;

- специализированный кейс для переноски и хранения.

- электронный блок твердомера ТКМ-359С со встроенным аккумулятором;

- датчик тип "D" с разъемом;

- датчик тип "E" с разъемом;

- датчик тип "G";

- соединительный кабель к твердомерам серии ТКМ-359 - 2 шт.;

- насадка Z-359;

- контрольный образец твердости НВ;

- зарядное устройство;

- руководство по эксплуатации (совмещенное с паспортом);

- свидетельство о поверке (или отметка в РЭ);

- программное обеспечение на CD-диске;

- USB-кабель для подключения к ПК;

- чехол и манжета для закрепления прибора на груди (руке);

- сумка для переноски и хранения;

- специализированный кейс для переноски и хранения.

| Manual для TKM-359C |

Measurement parameters | |

| Rockwell measurement range, HRC | from 20 to 70 |

| Rockwell measurement error, HRC | 1,5 |

| Measurement error on the Brinell scale, HB | 10 |

| Brinell scale measurement range, HB | from 90 to 450 |

| Vickers scale measurement range, HV | from 240 to 940 |

| Vickers scale measurement error, HV | 12 |

| Number of measurements to determine the average hardness value | from 1 to 99 |

Performance | |

| Measurement time, s | 2,00 |

Control parameters | |

| Roughness of the controlled surface, no more, Ra | 3,2 (sensor D) / 7,6 (sensor G) / 3,2 (sensor E) |

| The thickness of the controlled item, not less, mm | 6 (sensor D) / 55 (sensor G) / 6 (sensor E) |

| Recommended weight of the controlled item, kg | 3 (sensor D) / 3 (sensor E) / 6 (sensor G) |

Signal display | |

| Chart view | relative to the mean / relative to the value set by the user / relative to the range set by the user |

Calibration | |

| Number of additional individual calibrations per scale | 5 |

| Number of user-definable scales | 3 |

Memory | |

| Number of results stored | 12 400 |

Automatic signaling of defects | |

| Signaling that the measurement result is out of range | yes |

Interface | |

| USB | yes |

Display | |

| Screen type | color TFT |

| Screen output types | previous measurement results / additional statistical processing results / out-of-range results / user-defined |

Power supply | |

| Work without power supply | yes |

Batteries | |

| Battery type | Li-ion |

Dimensions and weight | |

| Height, mm | 121,0 |

| Width, mm | 69 |

| Thickness, mm | 41,0 |

| Weight, kg | 0,300 |

Operating conditions | |

| Operating temperature range, °C | from -15 to +35 |

Service life and warranty | |

| Warranty period, months | 32 |

There are no reviews for this product yet.. Write the first review.